PP hollow boxes are a type of packaging product made of corrugated plastic sheets. Although they have a similar appearance and usage to traditional corrugated paper, their unique advantages and longer service life have gradually made them a popular choice for packaging and transportation.

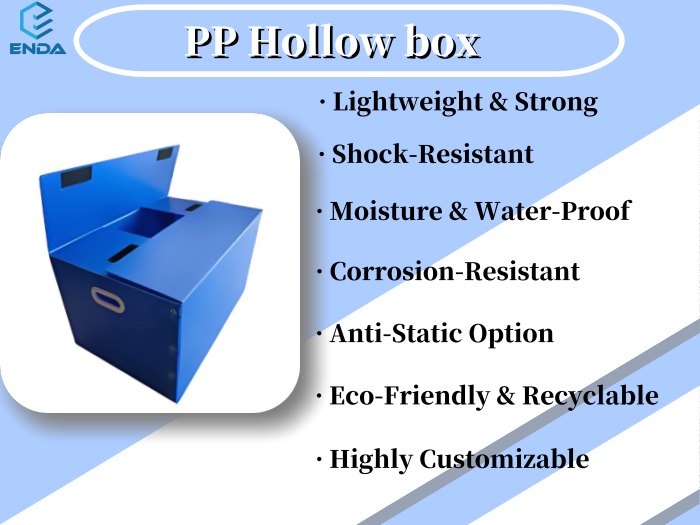

PP plastic hollow box with several features

PP plastic hollow box with several features

Lightweight & Strong: The hollow structure of corrugated plastic sheets makes pp hollow boxes over 50% lighter than wooden crates, which is convenient for transportation.

Shock-Resistant: The corrugated design provides excellent buffering for pp hollow boxes, minimizing damage to goods during transit from bumps and collisions.

Moisture & Water-Proof: Pure PP material prevents water absorption, avoiding deformation or mold, ensuring goods stay dry in humid conditions.

Corrosion-Resistant: Withstands acids, alkalis, and salts, suitable for packaging corrosive items and use in harsh chemical environments.

Anti-Static Option: By adding anti-static masterbatch, the surface of pp hollow box can protect sensitive electronics from static damage.

Eco-Friendly & Recyclable: Made of recyclable PP, non-toxic and pollution-free, reusable multiple times to reduce waste and environmental costs.

Highly Customizable: PP hollow boxes can be easily tailored in size, color, thickness and shape. Foldable designs save storage space, and accessories like dividers, wheels, or lids can be added.

Multi-use PP hollow box

Multi-use PP hollow box

Food Industry: PP hollow boxes are most commonly seen in the food packaging industry. Thanks to the pp plastic material that meets food standards, they can be used with peace of mind for both fruits and vegetables as well as seafood. At the same time, ensuring hygiene and safety during transport/storage, preventing food from getting damp and meeting food-grade standards.

Electronics Industry: Taking advantage of the anti-static and moisture-proof features of pp plastic, using pp hollow boxes to store precision components and circuit boards is a safe choice.

Logistics & Warehousing: Foldable PP hollow boxes can optimize storage space with stackability, and reduce long-term costs through durability and reusability.

Automotive Sector: PP hollow boxes are serves as turnover/transport boxes for engine and transmission parts, withstanding shocks to preserve precision.

Pharmaceuticals: PP hollow boxes meet strict requirements for moisture, mold, and static resistance, maintaining drug quality and stability.

Mechanical & Hardware: Thanks to impact and corrosion resistance of pp hollow boxes, they can protects parts, tools, and hardware from damage in tough industrial settings.

In conclusion, PP hollow boxes have outstanding features and wide applications. Meanwhile, they are also a good choice for cost savings. Unlike cardboard boxes that need to be replaced frequently or expensive wooden crates, pp hollow boxes are both durable and inexpensive, making them a cost-effective product for long-term use. Therefore, pp empty boxes have great competitiveness in the packaging and logistics industry and will gradually become the first choice for more people.

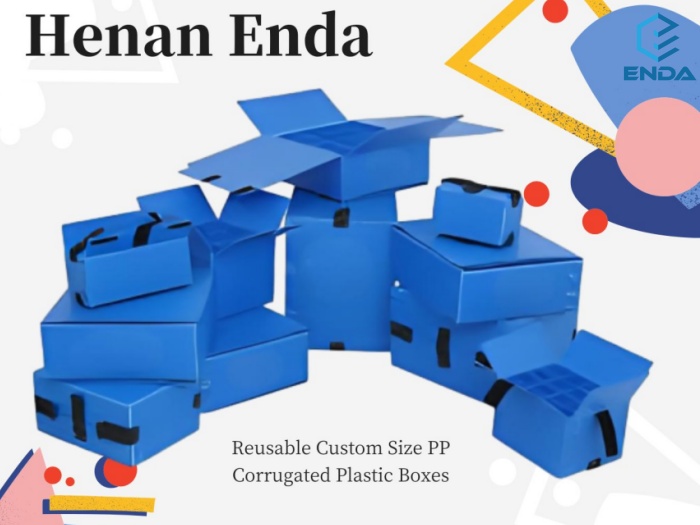

Henan Enda supplies pp plastic sheets & pp plastic products

Henan Enda supplies pp plastic sheets & pp plastic products

Henan Enda supplies a wide range of pp new material products. Whether you need pp plastic sheets or processed pp plastic products, and whether you need to customize the color, size, style or printed content of pp hollow boards and derivatives, you can customize them all at Henan Enda. You don't need to spend much time or effort. Just tell us your customization requirements and we can complete the production and shipment within 3-15 days. Welcome to contact us at any time.