Corrugated PP plastic sheets, renowned for their durability, lightweight nature, and water resistance, find extensive applications across packaging, construction, and agricultural sectors. Henan Enda Company—a leading manufacturer in China's PP plastic sheet industry—presents this article to outline its production process, assist in understanding corrugated plastic sheets manufacturing, and help you select a suitable producer.

Corrugated PP plastic sheets utilise polypropylene resin as their core material, endowing them with waterproofing, chemical resistance, and recyclability. PP material is blended with additives in precise proportions, incorporating functional agents such as UV stabilisers or flame retardants as required. These enhancements bolster the sheet's inherent properties, including resistance to sunlight or high temperatures.

Hih Quality polypropylene plastic material

Hih Quality polypropylene plastic material

This constitutes the pivotal stage in sheet formation. The blended raw materials are fed into an extruder, where they are heated and melted into a viscous state. The molten PP is then spirally advanced through a specialised corrugating die. The die's design determines the sheet thickness (typically 1.8-15mm) and corrugation dimensions. Throughout this process, manufacturers precisely control extrusion speed and temperature to ensure uniform thickness and a distinct corrugation pattern, guaranteeing the corrugated sheet's compressive strength.

The hot corrugated sheet is immediately conveyed through a cooling roller system. Circulating cold water within the rollers rapidly cools the PP plastic sheet, solidifying its shape. This step is crucial for preventing warping and enhancing structural stability. Advanced cooling systems maintain consistent temperatures, ensuring each sheet remains flat while preserving its corrugated structure.

Corrugated plastic sheets manufacturing process

Corrugated plastic sheets manufacturing process

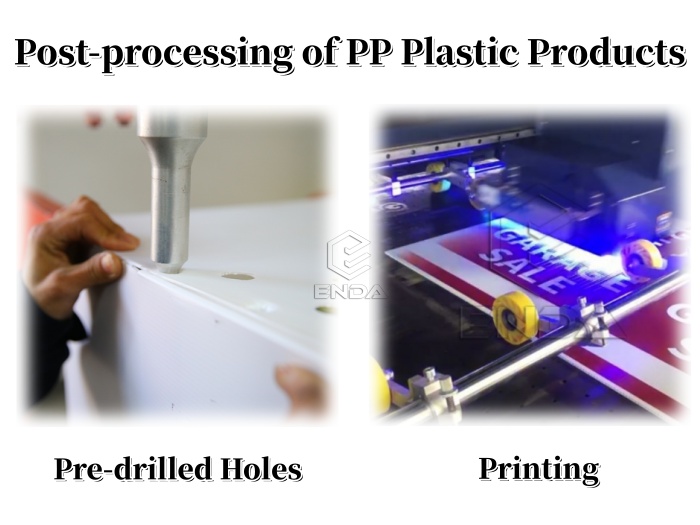

For clients with additional requirements, supplementary processing steps can be incorporated. For instance, Henan Enda Company can pre-drill holes for customers requiring corrugated plastic boxes or print custom designs for those needing garden signage. These finishing operations save clients both time and expense in sourcing separate processors.

Post-processing of pp plastic sheets

Post-processing of pp plastic sheets

The finished PP plastic sheets undergo trimming to remove uneven edges before being cut to standard sizes or customer-specified dimensions. Special shapes can also be produced upon request, such as foldable storage boxes, partitions, or uniquely shaped garden signs (e.g., houses, animals), enabling direct use by the customer.

Following quality inspection of the corrugated plastic sheets, packaging and dispatch proceed. As a PP sheet manufacturer with extensive cross-border trade experience, Henan Enda delivers customers' corrugated plastic sheets punctually via land, sea, or air freight logistics.

As a leading manufacturer with 14 years of expertise, Henan Enda operates multiple advanced extrusion production lines. This ensures efficient manufacturing while accommodating both small and large-volume orders, simultaneously reducing costs and offering competitive pricing. And the entire manufacturing process of pp corrugated plastic sheets is strictly implemented in accordance with standards to ensure uniformity of product quality. Furthermore, we support customised deep processing. At Enda, you can commission various corrugated PP plastic sheet products, including garden signs, packaging boxes, display stands, and tree protection sleeves, suitable for diverse industries.

Henan Enda pp plastic sheets manufacturer

Henan Enda pp plastic sheets manufacturer

Our dedicated design and technical support team assists in developing tailored solutions to produce products that meet your exacting standards. From material selection to after-sales support, we ensure a seamless collaborative experience.

If you’re looking for high-quality corrugated PP plastic sheets manufacturing factory, contact us today. Our team will provide a detailed quote and technical solutions tailored to your needs.